MARIE CURIE ACTIONS

MARIE CURIE ACTIONS

Project H2020-MSCA-IF-2015 – GA - 705944

High Performance Seasonal Solar Energy Latent Heat Thermal Storage Using

Low Grade, Low Melting Temperature Metallic (THERMOSTALL)

Project duration: 24 months (2016-2018); Grant value: € 195k

Funded by EUROPEAN COMMISSION Research Executive Agency

PI: Prof. K Mahkamov; MC Research Fellow: Dr. Carolina Costa;

Aim and Objectives

Energy storage

technologies have long been a subject of great interest to both academia and

industry. The aim of this project is to develop a novel, cost effective and

high performance Latent Heat Thermal Energy Storage System (LHTESS) for

seasonal accumulation of solar energy in increased quantities.

The major barrier for

currently used organic, salt and salt hydrates based Phase Change Materials is

their very low thermal conductivity coefficient and density, which results in

the relatively large volumes of storage systems and difficulties in achieving

the necessary rates of thermal energy re-charge and discharge, even when using

advanced heat exchangers.

The new approach to

overcome the above issues is the deployment of low grade, low

melting temperature metallic alloys (ELMTAs). The ELMTAs are currently produced

for application in other industrial sectors (e.g. electronics) and have not

been actively considered for the thermal energy accumulation with the exception

of very limited studies. Their heat conduction is two orders of magnitude

greater than that of conventional PCMs and they are stable and can provide the thermal

storage capacity which is 2-3 times greater per unit of volume due to the

greater densities.

The project consists of

both theoretical and experimental investigations. A range of low grade ELMTAs

for application in LHTESS have been selected and their thermophysical

properties are being studied using Differential Scanning Calorimetry and

thermal conductivity analysis. Thermal cycling tests of such alloys are also being

conducted.

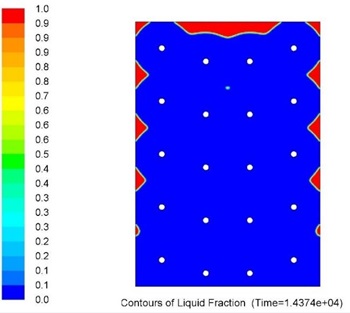

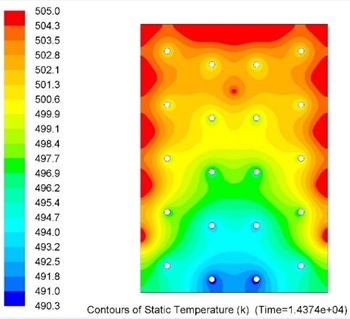

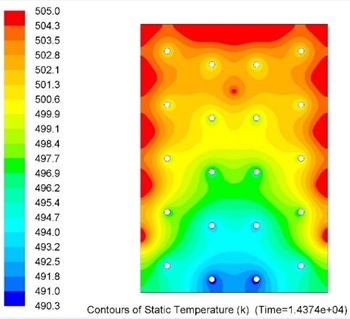

Numerical investigations

of heat transfer and flow in the LHTESS with ELMTAs will be performed.

Experimental studies of heat transfer and flow in a laboratory prototype of the

LHTESS with ELMTAs will be conducted. As outcomes of investigations,

dimensionless heat transfer correlations will be derived and design

recommendations for a practical solar energy seasonal LHTESS with the low grade

ELMTA will be produced for a project industrial partner.

Brief description of Literature analysis

Through literature

analysis shows that here is no a clear consensus about the use of metallic materials

as PCMs (MPCMs) for LHTES. The low thermal conductivity of the common PCMs,

leads to the need for bigger heat exchange surfaces or embedding metal or

graphite/carbon structures into the PCMs to enhance their performance. Such the

approach negatively affects the feasibility of LHTES [1,

2].

On the other hand, metallic PCMs (MPCMs)

have a significant advantage in thermal

conductivity and this parameter does not require enhancing [3-8]. However, there are a number of

research works [9-13] which highlight the low heat of fusion per unit weight [4,

6-8, 12, 14], high degree of sub-cooling and their relatively high cost, compared to

that of more conventional PCMs. To date, metal alloys have not been endorsed as

effective PCMs although they have also some additional advantages such as high

density, low corrosiveness and small

volume change during melting and solidification [17].

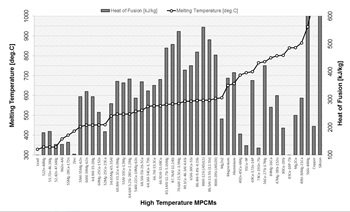

For high temperature

applications aluminium alloys were investigated in [15] as potential PCMs (>300 °C) because of

their high latent heat and good thermal stability.

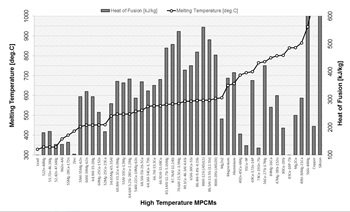

Information on the lowest

reported values of the heat of fusion for high

temperature MPCMs is summarised in Fig. 1. It can be seen that eutectic

aluminium alloys have the highest heat

of fusion in the group considered. With regard to the cost and availability of the materials, prices for Mg, Zn, Si and Al are approximately

between 2 and 3 $/kg and these materials are widely used in various industrial

applications [16].

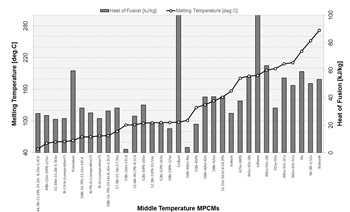

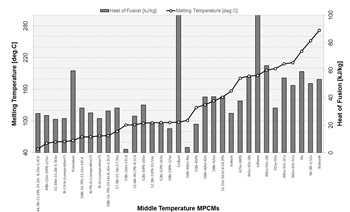

For the mid- temperature

range (between 48 and 124 °C), metals with the low melting temperature or

alloys based on elements such as Bi, Pb, Sn, Cd, In, Ga, Zn, Sb etc., are

available. Low-melting-point alloys are extensively used in the fields of materials

processing, electronics, electrical automatic control, continuous casting

simulation, welding etc. [17, 18]. Bismuth is one

of the major components of many fusible alloys, which strongly influence the value

of melting point, and has the unique

characteristic, namely it expands during

solidification process [19]. Summary of

information on melting temperatures and heat of fusion of some mid-temperature

MPCMs, investigated in a number of studies, is presented in Fig. 2.

Many of alloys, which

could be deployed in the mid-temperature range, contain harmful elements, such

as lead (Pb). Lead is considered as one of the top 17 chemicals, harmful for

human life and environment. This is highlighted by the Environmental Protection

Agency (EPA) and the European Union's RoHS (Restriction of Hazardous Substances

in Electrical and Electronic Equipment). Therefore, lead containing materials

should be treated with special

protection measures put in place.

Lead-free solders

were studied in [20-31] with relevant

databases have been created [32-34]. Three most

frequently referenced lead-free alloys to substitute the Pb-Sn eutectic composition

solder are Sn–Ag–Cu (near eutectic), Sn–Zn (eutectic) and Sn–Bi (eutectic) composites.

At present, the Sn– (3–4) wt% Ag–(0.5–0.9) wt% Cu alloy

is preferred for application in soldering [21]. This is due to a

number of factors, that affect the soldering process, namely mechanical properties,

melting point, cost, availability and wetting property. Furthermore, Pb-free solders are used because of their cost competitiveness. in order to maintain acceptable costs of

production in electronic industry. On elemental basis, Pb and Zn are the

cheapest metals, whilst In is more

expensive than Ag.

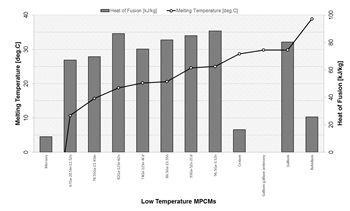

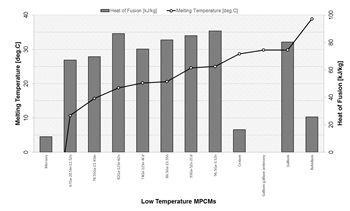

At the low-temperature

range (about 40 °C), liquid metals or low melting point alloys have been

studied and used for diverse applications, mainly as thermal management in

electronic devices. Room temperature liquid metals seem to meet most of the

requirements for meeting thermal comfort requirements [6]. Fig. 3 presents summary of gathered information on the melting temperatures and heat of

fusion for such the low-temperature MPCMs.

At the low-temperature

range (about 40 °C), liquid metals or low melting point alloys have been

studied and used for diverse applications, mainly as thermal management in

electronic devices. Room temperature liquid metals seem to meet most of the

requirements for meeting thermal comfort requirements [6]. Fig. 3 presents summary of gathered information on the melting temperatures and heat of

fusion for such the low-temperature MPCMs.

Selected ELMTAs and their Characterization

Eight commercially

available ELMTAs were selected as potential candidates as PCMs for the seasonal

thermal storage (see Fig. 4):

|

Name

|

Chemical

composition

|

Melting Point

|

|

Alloy 158F

|

50Bi-26.7Pb-13.3Sn-10Cd

|

70

|

|

Alloy 174F

|

57Bi-26In-17Sn (lead-free)

|

79

|

|

Alloy 203F

|

52.5Bi- 32Pb-15.5Sn

|

95

|

|

Alloy 281F

|

58.0Bi- 42.0Sn (lead-free)

|

138

|

|

Alloy 62S

|

62.5Sn- 36.1Pb- 1.4Ag

|

179

|

|

Alloy 63/37

|

63.0Sn- 37.0Pb

|

183

|

|

Alloy 96S

|

96.5Sn- 3.5Ag (lead-free)

|

221

|

|

Alloy 99C

|

99.3Sn- 0.7Cu

|

227

|

Alloys listed above are widely

used commercially in soldering processes and are described in the standard specifications for Low Melting

Point Alloys ASTM B774 [35] (<183 °C) and in Soft solder alloys BS-EN-ISO 9453 (<450 °C) [36]. The impurity

level in these commercial alloys is <0.15

wt.%.

Alloys listed above are widely

used commercially in soldering processes and are described in the standard specifications for Low Melting

Point Alloys ASTM B774 [35] (<183 °C) and in Soft solder alloys BS-EN-ISO 9453 (<450 °C) [36]. The impurity

level in these commercial alloys is <0.15

wt.%.

Differential Scanning

Calorimetry analysis was used to determine the latent heat, phase change

temperature and heat capacity of the selected ELMTAs as a function of the

temperature. DSC measurements were

performed in argon gas environment using a Setaram EVO131 Differential Scanning

Calorimeter. The DSC calibration was performed following the

Standard Test Method ASTM B1269 [37]. During the

measurements the DSC apparatus was purged with argon, all the weigh

measurements were carried out with the

accuracy of ± 0.01 mg. The calorimeter was calibrated with the melting point and enthalpy of

fusion for high-purity Sn. The ELMATs specimens were placed in aluminium

crucibles (30 mm)

and samples were thermally cycled 2-3 times with the heating and cooling rates

of 2 K/min. The maximum heating temperatures were set about 50 K higher than

the melting temperatures.

The above data obtained

for ELMTAs from literature review and experimental characterisation of thermal

properties was saved as database.

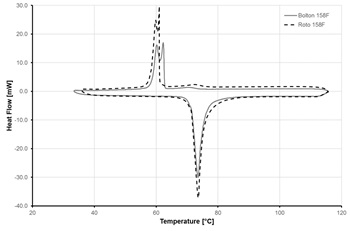

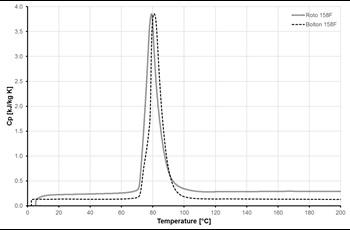

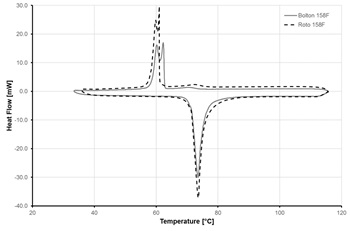

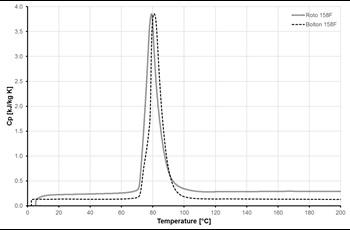

Figures 5 and 6 show samples

of results from DSC measurements for one

of the selected ELMATs, namely Alloy 158F. Bolton 158F and Roto 158F are the

same alloy, supplied by two different companies. Heating rate used in

measurements was 5 K/min.

Fig. 5 demonstrates the

significant temperature difference in the melting and crystallisation processes

(75 and 60 °C, respectively) which is caused by the slow rate of crystal

structure formation in metallic alloys.

The variation of the specific

heat capacity of the Alloy 158F as function of temperature, is shown in Fig.6

(the heating rate used was 20 K/min). This diagram indicates that the phase change

process takes place in the temperature range between 70 and 90 °C.

Most of MPCMs may have

this considerable temperature difference between melting and solidification

temperatures, which should be taken into account during thermal storage system

design and exploitation phases.

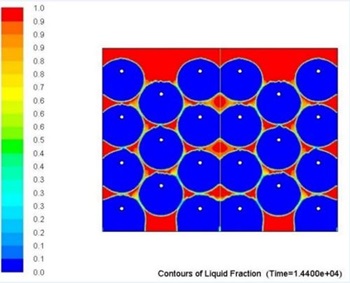

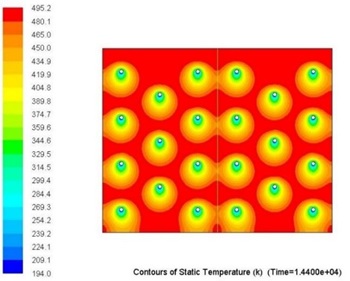

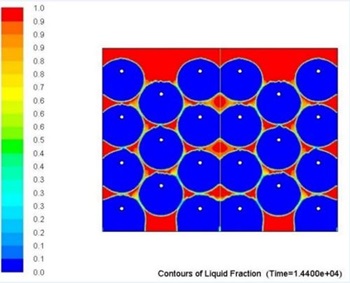

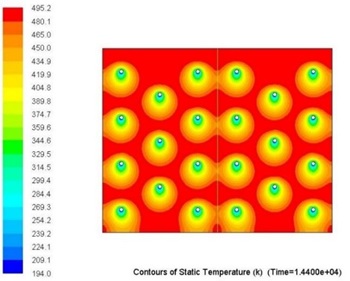

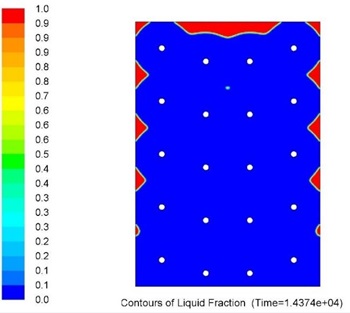

Overall metallic alloys

provide much superior performance in terms of heat charging and discharging

times. Figs. 7 and 8 below show comparison of this performance during

discharging process (solidification) for Tin and Solar Salt based thermal

storages with the same capacity. It can be clearly seen that during the same

period of time significantly more heat

was delivered to the user when the storage was metallic alloy based.

Current work

Several alloys were selected

for further investigations to determine the influence of higher levels of

impurity (>1wt.%) on their thermophysical properties as MPCMs.

Presently, measurements of the thermal conductivity as

a function of temperature for the selected MPCMS is ongoing.

The short-term

thermal stability experiments (100 cycles) using the DSC technique are being

run.

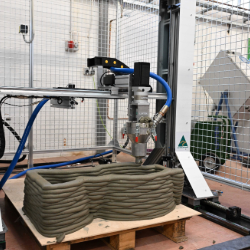

Numerical and experimental

investigations of heat transfer and flow in the laboratory prototype of LHTESS

with ELMTAs for deriving heat transfer correlations.

Practical Applications

Results obtained will be

used in the development of a novel

effective Solar Thermal Energy Storage systems for a small solar power plant

Innova MicroSolar - (Project 723596 - H2020-EE-2016-2017/H2020-EE-2016-RIA-IA, 2016-2020).

Additionally, outcomes

will be used in R&D activities of the industrial partner in THERMOSTALL

Project.

References

[1] F. Agyenim, N. Hewitt, P. Eames, and

M. Smyth, "A review of materials, heat transfer and phase change problem

formulation for latent heat thermal energy storage systems (LHTESS)," Renewable and Sustainable Energy Reviews, vol.

14, pp. 615-628, 2010.

[2] J. P. Kotzé,

"Thermal energy storage in metallic phase change materials," Doctor

of Philosophy, Faculty of Engineering, Stellenbosch University, 2014.

[3] M. M. Kenisarin,

"High-temperature phase change materials for thermal energy storage," Renewable and Sustainable Energy Reviews, vol. 14, pp. 955-970, 2010.

[4] H. Ge and J. Liu,

"Phase change effect of low melting point metal for an automatic cooling

of USB flash memory," in Frontiers

in Energy vol. 6, ed, 2012, pp. 207-209.

[5] M. Liu, W. Saman,

and F. Bruno, "Review on storage materials and thermal performance

enhancement techniques for high temperature phase change thermal storage

systems," Renewable and Sustainable

Energy Reviews, vol. 16, pp. 2118-2132, 2012.

[6] H. Ge, H. Li, S.

Mei, and J. Liu, "Low melting point liquid metal as a new class of phase

change material: An emerging frontier in energy area," Renewable and Sustainable Energy Reviews, vol.

21, pp. 331-346, 2013.

[7] S. A. Mohamed, F.

A. Al-Sulaiman, N. I. Ibrahim, M. H. Zahir, A. Al-Ahmed, R. Saidur, et al., "A review on current

status and challenges of inorganic phase change materials for thermal energy

storage systems," Renewable and

Sustainable Energy Reviews, vol. 70, pp. 1072-1089, 2017.

[8] B. Cárdenas and N.

León, "High temperature latent heat thermal energy storage: Phase change

materials, design considerations and performance enhancement techniques," Renewable and Sustainable Energy Reviews, vol.

27, pp. 724-737, 2013.

[9] M. M. Farid, A. M.

Khudhair, S. A. K. Razack, and S. Al-Hallaj, "A review on phase change

energy storage: materials and applications," Energy Conversion and Management, vol. 45, pp. 1597-1615, 2004.

[10] A. M. Khudhair and

M. M. Farid, "A review on energy conservation in building applications

with thermal storage by latent heat using phase change materials," Energy Conversion and Management, vol.

45, pp. 263-275, 2004.

[11] A. Gil, M. Medrano,

I. Martorell, A. Lázaro, P. Dolado, B. Zalba,

et al., "State of the art on high temperature thermal energy storage

for power generation. Part 1—Concepts, materials and modellization," Renewable and Sustainable Energy Reviews, vol.

14, pp. 31-55, 2010.

[12] A. Sharma, V. V.

Tyagi, C. R. Chen, and D. Buddhi, "Review on thermal energy storage with

phase change materials and applications," Renewable and Sustainable Energy Reviews, vol. 13, pp. 318-345,

2009.

[13] N. Soares, J. J.

Costa, A. R. Gaspar, and P. Santos, "Review of passive PCM latent heat

thermal energy storage systems towards buildings’ energy efficiency," Energy and Buildings, vol. 59, pp.

82-103, 2013.

[14] T. Khadiran, M. Z.

Hussein, Z. Zainal, and R. Rusli, "Advanced energy storage materials for

building applications and their thermal performance characterization: A

review," Renewable and Sustainable

Energy Reviews, vol. 57, pp. 916-928, 2016.

[15] J. Q. Sun, R. Y.

Zhang, Z. P. Liu, and G. H. Lu, "Thermal reliability test of Al–34%Mg–6%Zn

alloy as latent heat storage material and corrosion of metal with respect to

thermal cycling," Energy Conversion

and Management, vol. 48, pp. 619-624, 2007.

[16] P.

Blanco-Rodríguez, J. Rodríguez-Aseguinolaza, E. Risueño, and M. Tello,

"Thermophysical characterization of Mg–51%Zn eutectic metal alloy: A phase

change material for thermal energy storage in direct steam generation applications," Energy, vol. 72, pp. 414-420, 2014.

[17] K. Zhou, Z. Tang,

Y. Lu, T. Wang, H. Wang, and T. Li, "Composition, Microstructure, Phase

Constitution and Fundamental Physicochemical Properties of Low-Melting-Point

Multi-Component Eutectic Alloys," Journal

of Materials Science & Technology, vol. 33, pp. 131-154, 2017.

[18] Z. Mei, H. A.

Holder, and H. A. V. Plas. (1996) Low-Temperature Solders. Hewlett-Packard Journal.

[19] I. Corporation,

"How to Use Fusible Alloys," INDIUM Corporation.

[20] M. Abtew and G.

Selvaduray, "Lead-Free Solders in Microelectronics," Master Science and Engineering, vol. 27,

pp. 95-141, 2000.

[21] K. Suganuma,

"Advances in lead-free electronics soldering," Current Opinion in Solid State and Materials Science, vol. 5, pp.

55–64, 2001.

[22] H. MAVOORI, A. G.

RAMIREZ, and S. JIN, "Lead-Free Universal Solders for Optical and

Electronic Devices," Journal of

ELECTRONIC MATERIALS, vol. 31, 2002.

[23] D. T. Siewert, D.

S. Liu, D. D. R. Smith, and M. J. C. Madeni, "Properties of Lead-Free

Solders," NIST2002.

[24] F. S. Mhiaoui,

"Physical properties of lead free solders in liquid and solid state,"

doctor rerum naturalium, Technischen Universität Chemnitz, 2007.

[25] C. Handwerker, U.

Kattner, M. Gaithersburg, K.-W. Moon, and M. Gaithersburg, "Chapter 2:

Fundamental Properties of Pb-Free Solder Alloys," in Lead-Free Soldering, ed, 2007.

[26] A. A. El-Daly, Y.

Swilem, M. H. Makled, M. G. El-Shaarawy, and A. M. Abdraboh, "Thermal and

mechanical properties of Sn–Zn–Bi lead-free solder alloys," Journal of Alloys and Compounds, vol.

484, pp. 134-142, 2009.

[27] M. Palcut,

J.Sopoušek, L. Trnková, M. Turňa, E.Hodúlová, J. Janovec, et al., "Thermal analysis of selected tin-based lead-free

solder alloys," Kovove Mater., vol.

47, pp. 43-50, 2009.

[28] Yucai Hu, Fengjing

Cao, Fangxiao Li, G. Ni, and a. X. Cui, "RESEARCH PROGRESS ON LEAD-FREE

SOLDERS," 150 Rev. Adv. Mater. Sci., vol. 29, pp. 150-155, 2011.

[29] A. A. El-Daly, A.

E. Hammad, G. S. Al-Ganainy, and A. A. Ibrahiem, "Design of lead-free

candidate alloys for low-temperature soldering applications based on the

hypoeutectic Sn–6.5Zn alloy," Materials

& Design (1980-2015), vol. 56, pp. 594-603, 2014.

[30] Y. Shu, K.

Rajathurai, F. Gao, Q. Cui, and Z. Gu, "Synthesis and thermal properties

of low melting temperature tin/indium (Sn/In) lead-free nanosolders and their

melting behavior in a vapor flux," Journal

of Alloys and Compounds, vol. 626, pp. 391-400, 2015.

[31] A. A. El-Daly, A.

M. El-Taher, and S. Gouda, "Development of new multicomponent Sn–Ag–Cu–Bi

lead-free solders for low-cost commercial electronic assembly," Journal of Alloys and Compounds, vol.

627, pp. 268-275, 2015.

[32] Z. Moser, W.

Gąsior, A. Dębski, and J. Pstruś, SURDAT:

DATABASE OF LEAD - FREE SOLDERING MATERIALS. Kraków, 200.

[33] M. C. Schmetterer,

P. A. Mikula, and P. H. Ipser, "DATABASE FOR PROPERTIES OF LEAD-FREE

SOLDER ALLOYS," 2006.

[34] W. Gąsior, Z.

Moser, A. Dębski, and T. Siewert, "Integration of the NIST and SURDAT

Databases on Physical Properties of Lead-Free Solder Alloys," International Journal of Thermophysics, vol.

31, pp. 502-512, 2010.

[35] ASTM, "ASTM B

774 – 00: Low Melting Point Alloys (Standard)," ed, 2000.

[36] BS, "BS EN

29453-1994: Soft solder alloys — Chemical compositions and forms

(Standard)," ed, 1994.

[37] ASTM, "ASTM

E1269: Standard Test Method for Determining Specific Heat Capacity by

Differential Scanning Calorimetry," ed.

Contacts

Emails: khamid.mahkamov@northumbria.ac.uk Phone: + 44 191 243 7510

carolina.costa@northumbria.ac.uk Phone: + 44 191 243 7649

MARIE CURIE ACTIONS

MARIE CURIE ACTIONS

At the low-temperature

range (about 40 °C), liquid metals or low melting point alloys have been

studied and used for diverse applications, mainly as thermal management in

electronic devices. Room temperature liquid metals seem to meet most of the

requirements for meeting thermal comfort requirements [6]. Fig. 3 presents summary of gathered information on the melting temperatures and heat of

fusion for such the low-temperature MPCMs.

At the low-temperature

range (about 40 °C), liquid metals or low melting point alloys have been

studied and used for diverse applications, mainly as thermal management in

electronic devices. Room temperature liquid metals seem to meet most of the

requirements for meeting thermal comfort requirements [6]. Fig. 3 presents summary of gathered information on the melting temperatures and heat of

fusion for such the low-temperature MPCMs.  Alloys listed above are widely

used commercially in soldering processes and are described in the standard specifications for Low Melting

Point Alloys ASTM B774 [35] (<183 °C) and in Soft solder alloys BS-EN-ISO 9453 (<450 °C) [36]. The impurity

level in these commercial alloys is <0.15

wt.%.

Alloys listed above are widely

used commercially in soldering processes and are described in the standard specifications for Low Melting

Point Alloys ASTM B774 [35] (<183 °C) and in Soft solder alloys BS-EN-ISO 9453 (<450 °C) [36]. The impurity

level in these commercial alloys is <0.15

wt.%.